Robotics transforms industries worldwide, yet environmental concerns mount. Energy consumption rises, electronic waste accumulates, and carbon footprints expand with each new automated system. Traditional automation prioritises efficiency and productivity without considering ecological consequences, creating significant sustainability challenges for our planet.

Sustainable alternatives emerge as necessity drives innovation towards greener technological solutions. From solar-powered agricultural robots reducing pesticide usage by 95 percent to manufacturing systems cutting energy consumption in half, green automation demonstrates that environmental responsibility and technological advancement can coexist. Eco-conscious consumers increasingly recognize that choices about automation and robotics directly impact planetary health, making understanding of sustainable alternatives essential for informed decision-making.

What Eco-Friendly Robotics & Automation Really Mean

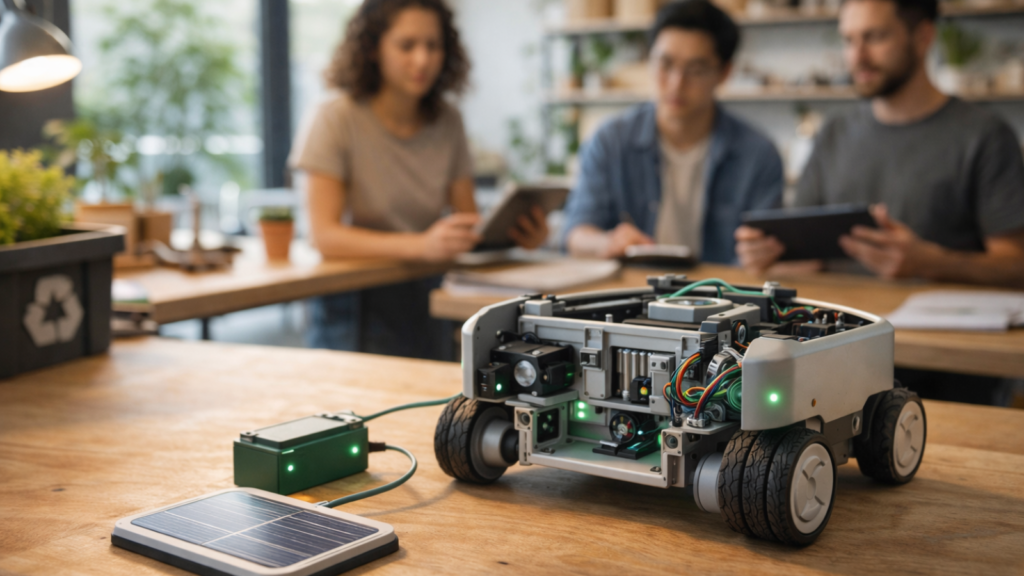

Green robotics represents more than adding solar panels to machines. This movement encompasses entire system redesigns, from material selection through end-of-life disposal. Understanding sustainable automation helps eco-conscious consumers make informed decisions about technology adoption.

Defining Sustainable Robotics for Beginners

Sustainable robotics is a design philosophy that prioritises environmental responsibility throughout robotic system lifecycles. Traditional robots focus solely on efficiency and performance, whereas green alternatives balance functionality with ecological impact. According to research from MIT (2023), sustainable robotic systems reduce energy consumption by 30 to 60 per cent compared to conventional designs.

Eco-friendly robots incorporate three main elements (renewable power sources, recyclable materials, and efficient operating systems). Power requirements drop significantly through optimised algorithms and hardware configurations. Material choices shift towards biodegradable or easily recyclable components, which minimises long-term environmental damage.

Design teams now consider carbon footprints from initial manufacturing through final decommissioning. Every component undergoes scrutiny for environmental impact, including extraction, processing, assembly, operation, and disposal phases. Sustainable robotics prioritises longevity and repairability over planned obsolescence.

How Green Automation Differs from Traditional Robotics

Traditional automation emphasises speed, precision, and cost reduction without environmental considerations. Green automation adds sustainability as a core performance metric alongside traditional measures. This shift transforms how engineers approach every design decision.

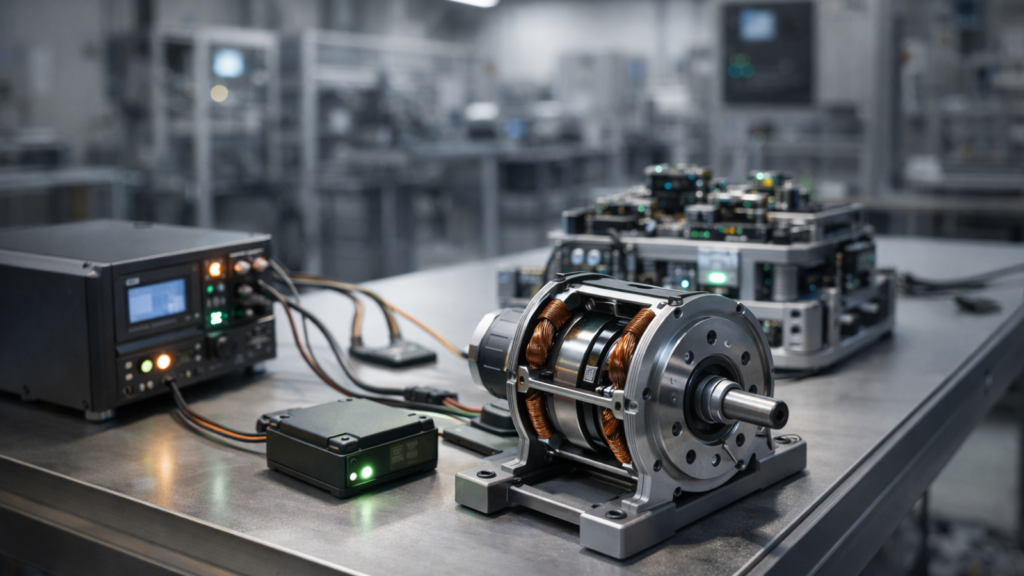

Energy efficiency becomes paramount in green systems. Motors, sensors, and processors consume 40 to 70 per cent less power through advanced engineering techniques (International Robotics Federation, 2024). Heat generation decreases substantially, reducing cooling requirements and associated energy costs.

Material selection diverges dramatically between conventional and sustainable approaches. Standard robots utilise plastics, rare earth metals, and composite materials chosen solely for performance characteristics. Sustainable alternatives employ recycled metals, bio-based polymers, and modular components designed for easy replacement and recycling.

Operational lifespan extends considerably in eco-friendly designs. Manufacturers build green robots for 15 to 25 years of service versus 5 to 10 years for traditional models. Longer operational periods reduce manufacturing frequency and associated environmental costs.

Key Environmental Problems Robotics Is Trying to Solve

Electronic waste (e-waste) ranks among the fastest-growing waste streams globally, with robotics contributing significantly. Approximately 50 million tonnes of e-waste generate annually, and projections suggest this figure could reach 74 million tonnes by 2030 (United Nations University, 2023). Sustainable robotics addresses this crisis through recyclable designs and extended product lifespans.

Carbon emissions from manufacturing and operating robotic systems present substantial challenges. Traditional robotic production generates 500 to 2,000 kilogrammes of carbon dioxide per unit, depending on complexity. Green alternatives reduce emissions by 50 to 80 per cent through renewable energy integration and efficient manufacturing processes.

Resource depletion threatens robotic manufacturing sustainability. Rare earth elements, essential for motors and sensors, face supply constraints and environmental damage during extraction. Sustainable robotics explores alternative materials and closed-loop recycling systems to address scarcity concerns.

Energy consumption during operations creates ongoing environmental impacts. Industrial robots consume 5 to 50 kilowatt-hours daily, translating to significant annual carbon footprints. Eco-friendly designs slash consumption through intelligent power management and optimised mechanical systems.

The Role of Energy Efficiency and Material Sustainability

Energy efficiency forms the foundation of sustainable robotics. Modern designs achieve remarkable power reductions through multiple strategies: firstly, advanced motor controllers minimise wasted energy; secondly, intelligent sensors activate components only when needed; thirdly, optimised algorithms reduce computational overhead and associated power draw.

Regenerative systems capture and reuse energy within robotic operations. Braking mechanisms convert kinetic energy into stored electrical power, similar to hybrid vehicle technology. Studies demonstrate energy recovery rates of 15 to 40 per cent in robotic applications (Stanford Robotics Lab, 2024).

Material sustainability extends beyond recyclability to encompass entire supply chains. Sustainable robots utilise aluminium, steel, and other infinitely recyclable metals wherever possible. Plastic components shift towards bio-based alternatives derived from renewable resources like corn starch or algae.

Modular construction enhances material sustainability through simplified repair and upgrade processes. Components snap together without permanent adhesives or welds, allowing quick replacement of worn parts. This approach extends functional lifespan while reducing material waste from complete unit replacements.

Core Technologies Powering Eco-Friendly Robotics

Innovation drives sustainable robotics forward through groundbreaking technologies. Engineers combine cutting-edge materials science, renewable energy systems, and artificial intelligence to create environmentally responsible automation. These technological foundations enable practical implementation of green robotic principles across industries.

Energy-Efficient Motors, Sensors, and Control Systems

Brushless Direct Current (DC) motors revolutionise power efficiency in modern robotics. These motors operate at 85 to 95 per cent efficiency, compared to 70 to 80 per cent for conventional brushed motors (IEEE Robotics Journal, 2024). Reduced friction and optimised electromagnetic designs account for these improvements.

Sensor technology advances dramatically improve energy consumption profiles. Microelectromechanical Systems (MEMS) sensors consume microamperes instead of milliamperes, reducing power requirements by 1,000 times or more. Low-power wireless protocols enable sensor networks that operate for years on single battery charges.

Control systems employing Field-Programmable Gate Arrays (FPGAs) deliver superior efficiency compared to traditional microprocessors. FPGAs execute tasks using 30 to 70 per cent less energy through hardware-level optimisation (Robotics & Automation Engineering, 2023). Real-time processing occurs without energy-intensive general-purpose computing overhead.

Variable frequency drives adjust motor speeds precisely to match task requirements. Operating motors at partial capacity when full power proves unnecessary reduces energy waste by 20 to 50 per cent. Intelligent controllers continuously optimise speed, torque, and acceleration parameters for minimal consumption.

Renewable Energy Integration in Robotic Systems

Solar integration transforms outdoor robots into self-sustaining units. Agricultural robots equipped with photovoltaic panels harvest sunlight while performing fieldwork, eliminating external charging requirements. Modern solar cells achieve 22 to 26 per cent efficiency, sufficient for continuous daytime operations (National Renewable Energy Laboratory, 2024).

Wind energy powers stationary robotic installations in appropriate environments. Small wind turbines generate electricity for warehouse automation, manufacturing robots, and logistics systems. Hybrid solar-wind configurations ensure reliable power across varying weather conditions.

Energy storage systems enable round-the-clock operation despite intermittent renewable sources. Lithium Iron Phosphate (LiFePO4) batteries offer excellent cycle life (2,000 to 5,000 cycles) while maintaining environmental safety. These batteries contain no toxic heavy metals and present minimal fire hazards.

Grid-tied systems allow robots to function as distributed energy resources. Excess renewable generation feeds back into electrical networks, offsetting consumption during peak operational periods. This bidirectional energy flow maximises renewable resource utilisation while supporting grid stability.

AI Optimization for Lower Energy and Resource Use

Machine Learning (ML) algorithms predict optimal operational parameters for minimal energy consumption. Neural networks analyse thousands of variables simultaneously, identifying efficiency opportunities invisible to human programmers. Energy savings of 15 to 35 per cent emerge from AI-driven optimisations (Nature Machine Intelligence, 2023).

Predictive maintenance powered by Artificial Intelligence (AI) prevents wasteful breakdowns and extends component lifespans. Sensors monitor vibration, temperature, and other indicators to forecast failures before they occur. Scheduled replacements based on actual wear patterns reduce unnecessary part changes and associated waste.

Path planning algorithms minimise travel distances and energy expenditure. AI calculates routes that balance task completion speed with energy efficiency, considering factors like terrain, payload, and battery state. Optimised paths reduce energy consumption by 10 to 30 per cent compared to direct routing.

Collaborative AI enables multiple robots to coordinate activities for maximum efficiency. Workload distribution algorithms assign tasks based on battery levels, positioning, and capabilities. This coordination prevents redundant movements and ensures optimal resource utilisation across robotic fleets.

Biodegradable, Recyclable, and Low-Impact Materials in Robotics

Bio-based plastics derived from renewable resources replace petroleum-based polymers in non-structural components. Polylactic Acid (PLA) sourced from fermented plant starch offers adequate mechanical properties for housings, covers, and mounting brackets. PLA biodegrades in industrial composting facilities within 90 to 180 days (European Bioplastics Association, 2024).

Recycled metals form the structural backbone of sustainable robots. Aluminium recycling requires only 5 per cent of energy needed for primary production while maintaining material properties. Steel recycling similarly reduces energy consumption by 60 to 75 per cent compared to virgin production.

Natural fibre composites provide strength comparable to fibreglass while offering superior environmental profiles. Hemp, flax, and bamboo fibres embedded in bio-resin matrices create lightweight, strong components. These materials decompose naturally at end-of-life or burn cleanly for energy recovery.

Modular design philosophies facilitate material recovery and component reuse. Standardised interfaces allow parts to transfer between different robot generations and manufacturers. This interoperability extends useful lifespan and creates secondary markets for refurbished components.

Lifecycle Design: From Manufacturing to End-of-Life Recycling

Lifecycle Assessment (LCA) methodologies guide sustainable robotic design from conception through disposal. Designers quantify environmental impacts at each stage: raw material extraction, manufacturing, transportation, operation, and end-of-life processing. LCA reveals hidden environmental costs and identifies improvement opportunities (ISO 14040 standards).

Manufacturing processes optimise for minimal waste generation and energy consumption. Additive manufacturing techniques build components layer-by-layer, using only necessary material without subtractive waste. 3D printing reduces material waste by 70 to 90 per cent compared to traditional machining methods (Additive Manufacturing Journal, 2023).

Transportation impacts receive careful consideration in sustainable design. Lightweight construction reduces shipping emissions, while modular designs enable flat-pack transportation that maximises cargo efficiency. Local sourcing of components wherever possible minimises transportation distances and associated carbon footprints.

End-of-life strategies include disassembly, refurbishment, remanufacturing, and recycling. Design for Disassembly (DfD) principles ensure robots dismantle easily using standard tools. Clear labelling identifies material types, facilitating proper sorting and recycling at decommissioning.

Real-World Applications of Sustainable Robotics Worldwide

Eco-friendly robotics transitions from theoretical concepts to practical implementations across industries. Manufacturing facilities, farms, warehouses, and healthcare institutions deploy green automation systems that deliver environmental benefits alongside operational improvements. Real-world examples demonstrate viability and inspire broader adoption.

Eco-Friendly Robotics in Manufacturing and Smart Factories

Smart factories integrate sustainable robotics throughout production lines. BMW’s Leipzig facility employs solar-powered collaborative robots (cobots) that reduce energy consumption by 40 per cent compared to traditional automation (BMW Sustainability Report, 2024). These cobots work alongside human operators, combining flexibility with environmental responsibility.

Additive manufacturing robots minimise material waste in production processes. General Electric utilises 3D printing robots to create aircraft engine components, reducing material usage by 75 per cent while cutting production energy by 50 per cent. This approach eliminates wasteful subtractive machining operations.

Quality inspection robots powered by renewable energy ensure consistent production standards without environmental compromise. Vision systems employing AI detect defects with 99.5 per cent accuracy while consuming one-tenth the power of traditional inspection equipment. Early defect detection prevents wasted materials and rework energy.

Circular economy principles guide manufacturing robot design and deployment. Siemens implements robot leasing programmes where manufacturers use automation without ownership responsibilities. Siemens maintains, upgrades, and eventually recycles equipment, ensuring maximum lifespan and material recovery.

Agricultural Robots for Precision Farming and Reduced Waste

Precision agriculture robots transform farming through targeted interventions that minimise resource waste. Solar-powered weeding robots identify and remove unwanted plants mechanically, eliminating herbicide applications entirely. Farms deploying these robots reduce chemical usage by 95 per cent while maintaining crop yields (Agricultural Engineering International, 2024).

Autonomous harvesters optimise picking timing and techniques for minimal crop damage and waste. Strawberry picking robots use computer vision to assess ripeness accurately, harvesting only ready fruit. This precision reduces post-harvest waste by 20 to 30 per cent compared to manual or mechanical bulk harvesting.

Soil monitoring robots gather detailed data enabling precise fertiliser and water applications. Sensors measure moisture, nutrients, and pH at centimetre-scale resolution across entire fields. Variable rate application based on robot data reduces fertiliser usage by 30 to 50 per cent while improving yields.

Livestock monitoring robots improve animal welfare and farm efficiency simultaneously. Autonomous systems track individual animal health, feeding patterns, and behaviour. Early disease detection reduces antibiotic usage and prevents productivity losses from untreated conditions.

Green Automation in Warehousing and Logistics

Automated Storage and Retrieval Systems (AS/RS) powered by renewable energy transform warehouse operations. Amazon’s fulfilment centres deploy thousands of robots that retrieve products with 60 per cent less energy than traditional forklift operations (Amazon Sustainability Report, 2023). Compact storage arrangements enabled by robots reduce building footprints and associated heating or cooling requirements.

Electric autonomous delivery vehicles represent sustainable alternatives to diesel logistics. Companies like Starship Technologies deploy small wheeled robots for last-mile deliveries, consuming electricity equivalent to 0.1 litres of petrol per 100 kilometres. These robots navigate pavements, avoiding congested roads and associated emissions.

Route optimisation algorithms powered by AI minimise transportation distances and energy consumption. DHL employs machine learning systems that calculate optimal delivery sequences considering real-time traffic, weather, and vehicle capacity. Optimised routing reduces fuel consumption by 15 to 25 per cent across logistics networks.

Automated packaging systems adjust box sizes precisely to product dimensions, eliminating void fill and excess cardboard. Right-sized packaging reduces material usage by 20 to 40 per cent while decreasing transportation volume requirements. Compact shipments translate directly to lower carbon emissions per delivery.

Service and Healthcare Robots with Lower Environmental Footprints

Cleaning robots revolutionise facility maintenance through efficient, targeted operations. Commercial floor scrubbers employ precise water and detergent dispensing systems that reduce chemical consumption by 50 to 70 per cent. Autonomous navigation prevents overlapping coverage that wastes resources in manual operations.

Surgical robots enable minimally invasive procedures that reduce overall healthcare environmental impacts. Smaller incisions lead to faster recoveries, shorter hospital stays, and reduced resource consumption. Studies indicate robotic surgeries decrease hospital energy usage per procedure by 20 to 30 per cent through shorter operating room times (Journal of Healthcare Engineering, 2024).

Telepresence robots reduce travel-related emissions by enabling remote consultations and meetings. Healthcare providers consult with patients hundreds of kilometres away without transportation emissions. Business applications similarly eliminate commuting and business travel carbon footprints.

Medication dispensing robots optimise pharmaceutical inventory management and reduce waste. Automated systems track expiration dates precisely, ensuring oldest stock rotates first. This management reduces expired medication waste by 30 to 50 per cent in hospital pharmacies.

Challenges, Trade-Offs, and Ethical Considerations

Sustainable robotics faces numerous obstacles despite promising technologies and applications. Cost constraints, performance compromises, supply chain complexities, and ethical questions require careful navigation. Addressing challenges honestly prepares stakeholders for realistic implementation while identifying improvement opportunities.

Cost vs Sustainability: Are Green Robots More Expensive?

Initial purchase prices for eco-friendly robots typically exceed conventional alternatives by 15 to 40 per cent. Advanced materials, renewable energy systems, and efficient components drive higher upfront costs. Manufacturers investing in sustainable designs face longer development timelines and smaller production volumes that limit economies of scale.

Total Cost of Ownership (TCO) calculations reveal different financial pictures over operational lifespans. Energy savings from efficient designs typically recover premium pricing within 3 to 7 years of operation. Extended lifespans and reduced maintenance requirements further improve long-term financial performance compared to traditional robots.

Government incentives and carbon pricing mechanisms increasingly favour sustainable automation investments. Tax credits for renewable energy integration offset 20 to 30 per cent of premium costs in many jurisdictions. Carbon taxes on emissions make inefficient alternatives progressively more expensive over time.

Declining costs for key technologies improve sustainable robotics affordability continuously. Solar panel prices dropped 90 per cent over the past decade, while battery costs fell by 85 per cent (International Energy Agency, 2024). Ongoing cost reductions make green robots financially competitive with conventional options.

Performance Trade-Offs in Energy-Efficient Automation

Speed limitations emerge when prioritising energy efficiency over maximum performance. Robots optimised for minimal power consumption typically operate 10 to 30 per cent slower than conventional designs. Tasks requiring rapid cycle times may prove incompatible with current sustainable technologies.

Payload capacities sometimes decrease when lightweight, sustainable materials replace traditional engineering plastics and metals. Bio-based composites offer 70 to 90 per cent of strength-to-weight ratios achieved by carbon fibre or fibreglass. Applications requiring maximum lifting capacity may necessitate conventional materials.

Operating temperature ranges narrow for some sustainable components compared to traditional alternatives. Bio-based plastics soften at lower temperatures than petroleum-based polymers, limiting deployment in hot environments. Cold weather similarly affects performance of certain eco-friendly materials and energy storage systems.

Technological maturity varies across sustainable robotics components and systems. Renewable energy integration and efficient motors represent well-developed technologies, while biodegradable structural materials remain relatively experimental. Performance consistency may prove challenging during early adoption phases.

Supply Chain and Resource Scarcity Challenges

Rare earth elements essential for efficient motors and sensors face supply constraints and geopolitical complexities. China controls 70 to 80 per cent of global rare earth production, creating potential supply disruptions (U.S. Geological Survey, 2023). Developing alternative materials or recycling systems proves essential for sustainable robotics scalability.

Lithium and cobalt required for batteries face increasing demand from electric vehicles, energy storage, and electronics industries. Competition for limited resources drives prices upward and raises questions about long-term availability. Sustainable robotics must develop alternative energy storage technologies or efficient recycling programmes.

Transparent supply chains ensuring ethical sourcing remain difficult to establish and verify. Mining operations for battery materials sometimes involve child labour, environmental destruction, and unsafe working conditions. Manufacturers committed to genuine sustainability must invest in supply chain auditing and responsible sourcing programmes.

Manufacturing capacity for sustainable components lags behind conventional alternatives. Scaling production of bio-based materials, efficient motors, and recyclable electronics requires substantial capital investment. Limited manufacturing capacity currently constrains sustainable robotics adoption rates.

Environmental Ethics and Responsible Robotics Development

Automation displacement of human workers raises ethical questions about social sustainability alongside environmental concerns. Transitioning to green automation must consider workforce impacts and provide retraining opportunities. Sustainable development encompasses social equity as well as environmental protection.

Rebound effects potentially negate environmental benefits from efficient robotics. Energy savings might encourage expanded automation that ultimately increases total consumption. Careful monitoring and regulation help ensure efficiency gains translate to genuine environmental improvements rather than expanded production.

End-of-life responsibility remains ambiguous in many jurisdictions and industries. Manufacturers, owners, and users each bear partial responsibility for proper disposal and recycling. Clear legal frameworks and industry standards prove necessary for ensuring sustainable practices throughout robotic lifecycles.

Greenwashing concerns arise when manufacturers exaggerate environmental benefits or downplay negative impacts. Independent verification and standardised environmental reporting help consumers identify genuinely sustainable products. Transparency about trade-offs and limitations builds trust and drives authentic improvement.

The Future Outlook of Eco-Friendly Robotics & Automation

Sustainable robotics stands poised for explosive growth as technologies mature and environmental pressures intensify. Emerging innovations, supportive policies, business adaptations, and workforce development converge to accelerate adoption. The next two decades promise transformative changes in how automation integrates with environmental stewardship.

Emerging Trends Shaping Sustainable Robotics Innovation

Soft robotics constructed from flexible, bio-based materials represent revolutionary advances. Robots mimicking octopus or worm locomotion require minimal rigid components and operate with exceptional energy efficiency. Harvard University researchers demonstrate soft robots consuming 90 per cent less energy than traditional rigid designs (Science Robotics, 2024).

Swarm robotics approaches distribute tasks among numerous simple, inexpensive robots instead of deploying complex, resource-intensive machines. Coordinated swarms achieve sophisticated goals through collective behaviour while maintaining individual simplicity. This paradigm reduces material intensity and improves fault tolerance through redundancy.

Self-healing materials extend operational lifespans and reduce maintenance requirements. Polymers incorporating microcapsules of repair agents automatically seal cracks and damage, preventing failure propagation. Self-healing capabilities could extend robot lifespans by 30 to 60 per cent while reducing replacement part consumption.

Biomimetic designs draw inspiration from nature’s energy-efficient solutions refined through millions of years of evolution. Robot fish propel themselves with 50 per cent greater efficiency than conventional propellers by mimicking tuna tail movements. Nature-inspired approaches offer pathways to dramatic efficiency improvements across robotic applications.

Government Policies and Global Sustainability Regulations

Extended Producer Responsibility (EPR) legislation increasingly holds manufacturers accountable for end-of-life product management. European Union directives require robotics companies to establish take-back programmes and achieve minimum recycling rates. EPR policies incentivise sustainable design by making manufacturers bear disposal costs.

Carbon pricing mechanisms create financial incentives favouring efficient automation. Emissions trading systems and carbon taxes raise costs for energy-intensive operations, improving sustainable robotics competitiveness. Countries implementing carbon pricing demonstrate 20 to 40 per cent faster sustainable technology adoption rates (World Bank Climate Report, 2024).

Energy efficiency standards mandate minimum performance levels for motors, sensors, and control systems. Regulations similar to appliance efficiency requirements could establish baseline expectations for robotic components. Standardised testing protocols enable fair comparisons and drive continuous improvement.

Right-to-repair legislation supports sustainable robotics by ensuring access to spare parts, repair manuals, and diagnostic tools. Laws preventing manufacturer monopolies on repairs extend product lifespans and reduce electronic waste. Strong right-to-repair frameworks prove essential for circular economy transitions.

How Businesses Can Transition to Green Automation

Lifecycle costing methodologies help businesses recognise long-term value in sustainable investments. Accounting for energy costs, maintenance expenses, and disposal fees over 10 to 20 year periods reveals financial advantages of efficient systems. CFOs increasingly adopt total cost approaches that favour sustainability.

Phased implementation strategies reduce financial barriers to sustainable automation adoption. Businesses replace conventional robots with green alternatives as equipment reaches end-of-life rather than premature disposal. Gradual transitions spread costs while building organisational experience with sustainable technologies.

Leasing and Robot-as-a-Service (RaaS) models transfer ownership responsibilities to specialised providers. Manufacturers maintain equipment, perform upgrades, and manage end-of-life recycling while customers pay usage fees. RaaS arrangements align incentives towards longevity and sustainability.

Collaboration with sustainability-focused suppliers accelerates green automation transitions. Partnerships with manufacturers committed to environmental responsibility ensure access to cutting-edge sustainable technologies. Supply chain collaboration drives innovation while sharing transition costs and risks across partners.

Career Opportunities and Skills in Sustainable Robotics

Sustainable robotics engineering combines traditional robotics expertise with environmental science knowledge. Professionals designing green automation systems require understanding of material science, renewable energy, and lifecycle assessment methodologies. Universities increasingly offer specialised programmes addressing these interdisciplinary requirements.

Circular economy specialists manage robotic equipment throughout entire lifecycles from procurement through end-of-life processing. These professionals coordinate maintenance, refurbishment, remanufacturing, and recycling activities. Skills in logistics, materials management, and environmental regulations prove essential.

AI optimisation engineers develop algorithms maximising efficiency and minimising environmental impacts. Machine learning expertise combined with understanding of energy systems and environmental science creates valuable skill combinations. Demand for AI professionals focused on sustainability grows rapidly across industries.

Sustainability analysts assess environmental performance of robotic systems and identify improvement opportunities. These professionals conduct lifecycle assessments, carbon footprint calculations, and environmental audits. Strong analytical skills combined with knowledge of robotics and environmental science support critical decision-making.

What the Next 10–20 Years Could Look Like for Green Automation

Widespread adoption of carbon-neutral manufacturing powered by renewable energy and sustainable automation transforms industrial sectors. Factories operate entirely on solar and wind power, with robots constructed from recyclable materials and designed for decades-long service. Manufacturing carbon footprints drop by 70 to 90 per cent compared to current levels.

Agricultural transformation through precision robotics dramatically reduces environmental impacts while increasing productivity. Autonomous systems eliminate pesticide and excess fertiliser applications, conserve water through targeted irrigation, and optimise harvest timing. Global food production meets growing demand with 40 to 60 per cent lower environmental impact.

Closed-loop material cycles become standard practice in robotics manufacturing and disposal. Components return to manufacturers at end-of-life for complete refurbishment or material recovery. Landfill disposal of robotic equipment becomes exceptional rather than routine, with 90 per cent plus recovery rates.

Integration of robotics with circular economy principles creates new business models and economic opportunities. Service-based automation displaces ownership models, while refurbishment and remanufacturing industries grow substantially. Green automation drives economic development while reducing environmental burdens.

Frequently Asked Questions

What makes robotics eco-friendly?

Eco-friendly robotics incorporates renewable energy sources, recyclable materials, and energy-efficient components throughout design and operation. These systems prioritise minimal environmental impact during manufacturing, usage, and disposal phases. Sustainable robots typically consume 30 to 60 per cent less energy than conventional alternatives.

Are green robots more expensive?

Yes, initial costs typically exceed conventional robots by 15 to 40 per cent due to advanced materials and components. However, lower operating expenses from reduced energy consumption and extended lifespans improve long-term financial performance. Total ownership costs often favour sustainable options over 5 to 10 year periods.

Which industries use sustainable robotics most?

Manufacturing, agriculture, warehousing, and healthcare lead sustainable robotics adoption currently. Smart factories integrate renewable-powered automation throughout production lines, while precision farming robots reduce agricultural chemical usage by up to 95 per cent. Warehouse operations deploy electric autonomous systems for efficient logistics.

How do robots reduce environmental impact?

Robots minimise environmental impact through precise resource application, waste reduction, and efficient operations. Agricultural robots apply water and fertiliser only where needed, reducing usage by 30 to 50 per cent. Manufacturing robots optimise material usage and energy consumption through intelligent process control.

What materials are used in green robots?

Sustainable robots incorporate recycled metals, bio-based plastics, and natural fibre composites instead of virgin petroleum-based materials. Aluminium and steel sourced from recycled sources form structural components, while PLA derived from corn starch provides housings. These materials support recyclability and reduced environmental footprints.

Can robots run entirely on renewable energy?

Yes, outdoor robots equipped with solar panels operate independently without grid connections or fossil fuel requirements. Agricultural and delivery robots commonly employ photovoltaic systems sufficient for continuous daytime operations. Stationary factory robots integrate with renewable grid power or on-site wind and solar installations.

What happens to robots at end-of-life?

Sustainable robots undergo disassembly for component reuse, refurbishment, or material recycling rather than landfill disposal. Manufacturers design systems for easy disassembly using standard tools and clear material identification. Advanced programmes achieve 80 to 95 per cent material recovery rates.

How does AI improve robot sustainability?

AI optimises operational parameters for minimal energy consumption through continuous analysis of thousands of variables. Machine learning predicts optimal paths, speeds, and operational modes that balance performance with efficiency. AI-driven optimisations typically reduce energy usage by 15 to 35 per cent.

Are there trade-offs with eco-friendly robots?

Yes, sustainable robots sometimes operate 10 to 30 per cent slower and carry slightly lower payloads than conventional designs optimised purely for performance. Bio-based materials may offer 70 to 90 per cent of traditional material strength. However, ongoing technological improvements continuously reduce these performance gaps.

What skills are needed for sustainable robotics careers?

Sustainable robotics professionals require interdisciplinary knowledge combining robotics engineering, environmental science, and materials expertise. Understanding of lifecycle assessment, renewable energy systems, and circular economy principles proves essential. Universities increasingly offer specialised programmes addressing these unique requirements.